Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

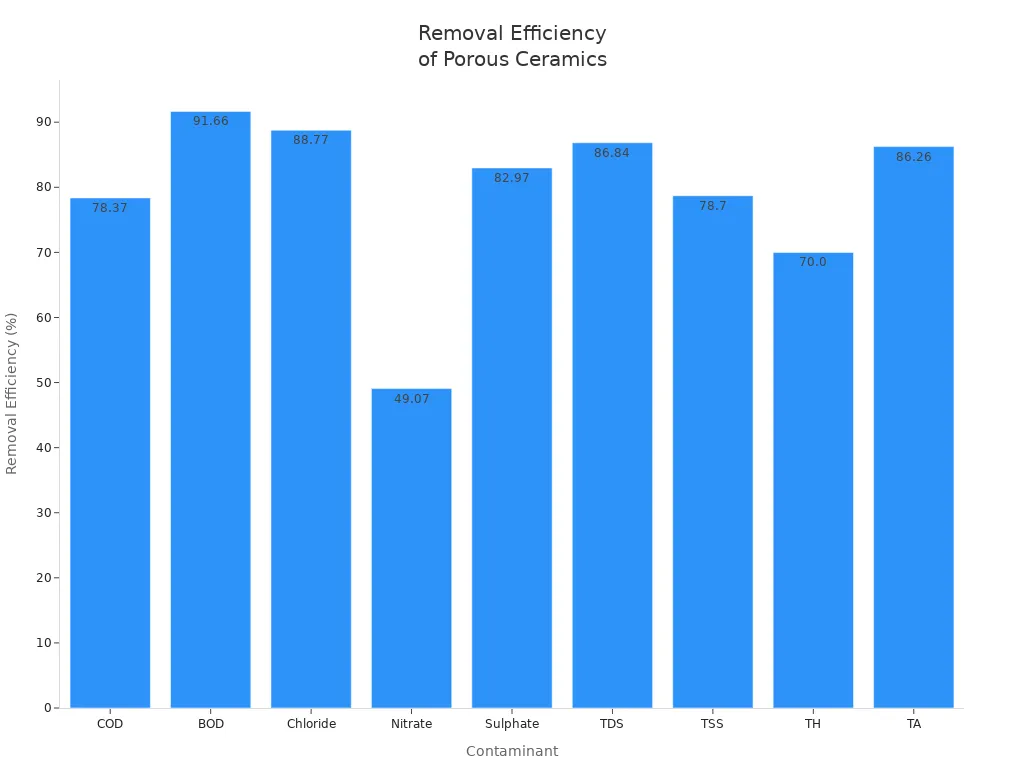

Porous ceramics for water treatment use a network of tiny, interconnected pores to trap and remove harmful substances from water. You benefit from their unique structure, which allows water to flow while capturing contaminants like bacteria, solids, and chemicals. These ceramics stand out because they combine high removal efficiency with long-lasting durability. For example, porous ceramic filters can remove up to 91.66% of BOD and 86.84% of TDS, making them more effective than many other materials.

You also see their growing importance worldwide, as the porous ceramics market for water treatment is projected to reach billions of dollars. This growth comes from stricter water standards and the need for reliable filtration.

Porous ceramics filter water by trapping harmful substances like bacteria and chemicals, making water safer to drink.

These materials are durable and can last up to five years with proper care, providing long-term filtration solutions.

Different pore sizes in ceramics allow for targeted filtration, so choose the right type based on your water treatment needs.

Regular maintenance, like cleaning and checking for cracks, is essential to keep ceramic filters working effectively.

Combining porous ceramics with other purification methods can enhance water safety, especially for removing viruses.

You encounter porous ceramics in many water treatment systems. These materials contain a network of tiny, interconnected pores. The pores increase the surface area, which helps trap and remove contaminants from water. Porous ceramics allow water to pass through while holding back particles, bacteria, and chemicals. You see their use in moisture absorption, humidification, and filtration. The classification of porous ceramics depends on pore size, which affects how well they separate and adsorb substances.

Porous ceramics play a key role in drinking water purification, exhaust gas filtration, air purification, and dust collection.

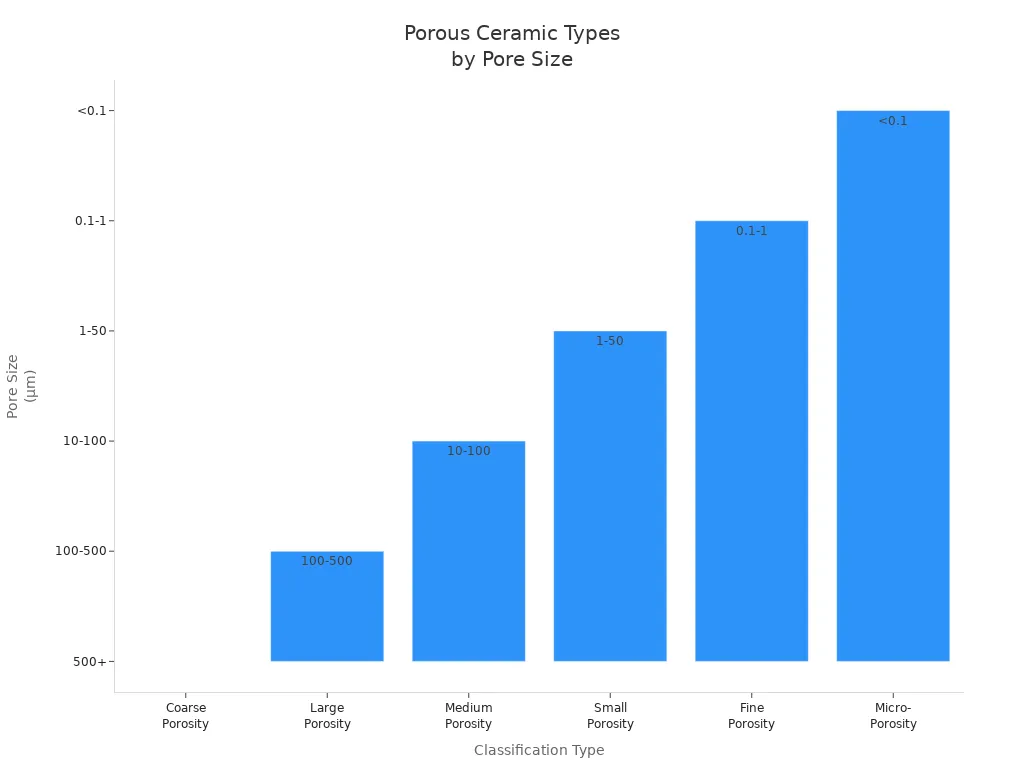

The classification of porous ceramics by pore size helps you choose the right material for your needs. The table below shows how these materials are grouped:

Classification Type | Pore Size Range |

|---|---|

Coarse Porosity | > 500 μm |

Large Porosity | 100 ~ 500 μm |

Medium Porosity | 10 ~ 100 μm |

Small Porosity | 1 ~ 50 μm |

Fine Porosity | 0.1 ~ 1 μm |

Micro-Porosity | < 0.1 μm |

You find that alumina ceramics usually have pore sizes from 1 to 100 micrometers, while silicon carbide ceramics range from 15 to 50 micrometers. These ranges help you match the right porous ceramic structures to specific water treatment tasks.

Porous ceramic structures feature a three-dimensional network of open pores. This design lets water flow through the material while trapping unwanted particles. You benefit from high porosity, which means more void spaces and faster water flow. The pore size distribution is crucial for removing microbes and other contaminants. When you use filters with larger pores, you get higher flow rates. However, high turbidity in source water can clog the pores and slow down filtration.

The fabrication of porous ceramics involves several techniques. You can see the most common fabrication methods in the table below:

Manufacturing Method | Description |

|---|---|

Organic Foam Impregnation Process | Impregnates ceramic slurry with organic foam, which burns off to create porous ceramics. |

Sol-Gel Process | Uses colloidal particles to form a controllable porous structure, often with nano-scale pores. |

Extruded Porous Honeycomb Ceramics | Shapes honeycomb ceramics using extrusion molding. |

Solid Phase Sintering Process | Fine particles sinter at joints of larger particles, creating three-dimensional through-holes. |

Gel Casting Process | Combines traditional molding with polymer reactions for a uniform green body before sintering. |

Freeze Drying Process | Controls ice growth direction to create ceramics with high porosity. |

Self-propagating High-temperature Synthesis | Uses exothermic reactions to make porous materials with high purity and porosity. |

Hydrothermal-hot Static Pressing Process | Employs water as a medium to create porous ceramics under high pressure and temperature. |

You notice that each fabrication technique affects the final pore size, shape, and distribution. These factors influence how well the ceramics perform in water treatment. When you select a fabrication method, you consider the desired porosity, mechanical strength, and chemical stability.

Porous ceramics made by solid phase sintering often have strong mechanical properties.

Freeze drying produces ceramics with very high porosity, which increases flow rates.

Sol-gel processes allow you to control pore size at the nano-scale for specialized filtration.

The open pore structure of porous ceramics gives you several advantages. You get faster water flow, higher filtration efficiency, and better removal of microbes. The flow rates of new ceramic filters are much higher than traditional filters. You can adjust the fabrication process to create ceramics that meet your specific water treatment needs.

You rely on porous ceramics for water treatment because they resist many harsh chemicals. Alumina ceramics show excellent strength and corrosion resistance. These materials withstand strong acids, bases, and cleaning agents. You can use them in environments where other materials might break down or lose effectiveness. The chemical stability of porous ceramics means you get reliable performance over time, even with repeated exposure to challenging water conditions.

Porous ceramics offer impressive mechanical strength, which you can measure by their ability to absorb water and withstand pressure. The strength depends on how you process the ceramics. For example:

Water absorption rates range from 17.6% to 23.0%, depending on sintering temperature and time.

Sintering at 950°C for 45 minutes gives the highest water absorption rate of 23.0%.

Longer sintering increases strength but lowers water absorption to 20.2% (60 min) and 19.5% (75 min).

Sintering at 1000°C results in water absorption rates of 21.3% (45 min) and 18.6% (60 min).

Adding 5% wood charcoal boosts both mechanical strength and water absorption, making the ceramics more practical for filtration.

You benefit from ceramics that balance strength and porosity, ensuring filters last longer and perform well under pressure.

Porous ceramics stand out for their ability to handle high temperatures. You can use them in water treatment processes that require heat without worrying about damage. Some ceramic filters operate at temperatures up to 1500°C. The table below shows the maximum operating temperatures for common ceramic materials:

Material | Maximum Operating Temperature |

|---|---|

Aluminum Oxide | 800°C |

Silicon Carbide | 1000°C |

Porous Ceramic Filter | 1500°C |

You see that these ceramics work in both hot and cold environments, making them versatile for many water purification systems.

Porous ceramics have several other important properties:

High permeability lets water flow easily through the filter, improving efficiency.

Electrical insulation protects against electrical hazards in treatment systems.

Abrasion resistance means you can use them in rough conditions without rapid wear.

Lightweight nature makes installation and maintenance easier.

Sound absorption helps reduce noise in water treatment facilities.

You can control porosity and pore size during manufacturing. Higher porosity increases permeability and water flow, but may lower mechanical strength. The table below shows how porosity affects flexural strength and pore diameter:

Porosity (%) | Flexural Strength (MPa) | Average Pore Diameter (µm) |

|---|---|---|

46 - 54 | 3 - 14 | 3.7 - 6.5 |

38 - 50 | 28 - 38 | N/A |

You adjust pore size and porosity to match your water treatment needs. Smaller pores trap finer particles, while larger pores allow faster flow. High permeability values, such as 1.48×10^-13 to 4.64×10^-13 m², show how well water moves through these ceramics. You also benefit from capillary rise, which helps transport water efficiently, especially in passive systems.

Tip: When you select porous ceramics, consider the balance between permeability, strength, and pore size to optimize your water treatment process.

You use porous ceramics in water treatment because they provide reliable filtration. The tiny pores in these ceramics, often as small as one-half micron, trap impurities as water passes through. The filter structure creates a maze of sharp angles, catching particles that penetrate the surface. This design allows you to remove fine particulates, bacteria, and sediment from water.

You benefit from the following filtration mechanisms:

Tiny pores trap contaminants.

The maze-like structure catches particles inside the filter.

Fine particulate filtration removes bacteria and sediment.

Porous ceramics excel at removing bacteria and protozoa. You see effective results when filtering out harmful microorganisms. However, viruses are much smaller than the pores in most ceramics, so you may need additional treatment steps for complete virus removal.

Tip: If you want to improve water safety, combine ceramic filtration with other purification methods to target viruses.

You find porous ceramic filters in household water purifiers, rural water systems, and emergency kits. These filters work well in gravity-driven systems, which means you do not need electricity. You can use them in decentralized locations, making them ideal for rural communities.

Porous ceramics also help you purify water through adsorption. The large surface area inside the porous structure attracts and holds contaminants. You can remove sediment, bacteria, protozoa, and even some viruses by using ceramics with enhanced adsorption properties.

Contaminant Type | Description |

|---|---|

Sediment | Particles that can cloud water and affect its quality. |

Bacteria | Harmful microorganisms that can cause illness. |

Protozoa | Single-celled organisms that can lead to waterborne diseases. |

Viruses | Pathogens that can cause serious health issues, such as rotavirus. |

You rely on porous ceramics to adsorb heavy metals from water. Different ceramic materials show high adsorption capacity for metals like copper, nickel, and cobalt. For example, diatomite-based porous ceramics can adsorb up to 4.5 mg of copper ions per gram after six hours. Mullite whiskers and cordierite ceramics also demonstrate high removal efficiency for copper.

Study | Heavy Metal | Adsorption Capacity |

|---|---|---|

Coal gangue-based porous ceramics | Ni2+, Cu2+, Co2+ | Measured over time |

Mullite Whiskers/Cordierite | Cu2+ | High removal efficiency |

Diatomite-based porous ceramics | Cu2+ | 4.5 mg/g after 6 h |

You can use porous ceramics to reduce chlorine and organic contaminants. The adsorption process helps you meet water safety standards and improve taste and odor.

You achieve better water purification results when you choose high-quality porous ceramics. These advanced filters remove over 99% of E. coli and rotavirus, making water much safer for drinking. The pore size in high-quality ceramics ranges from 0.1 to 10 micrometers, which blocks small particles and improves clarity.

Some high-quality porous ceramics feature special coatings that kill germs. You notice that these filters outperform standard grades, especially in removing bacteria and viruses. The structural integrity of these ceramics ensures long service life, even under tough conditions.

Key Indicator | Description |

|---|---|

Chlorine Reduction Capability | Measures the filter's ability to adsorb free chlorine. |

Total Organic Carbon (TOC) Removal | Assesses the filter’s efficiency in removing organic contaminants. |

Structural Integrity | Ensures the physical stability of the filter material under normal use conditions. |

Material Safety | All materials that come into contact with water must meet specific safety standards. |

You use high-quality porous ceramics in both urban and rural water treatment systems. In decentralized systems, you benefit from low energy consumption and simple operation. These filters last up to five years and require minimal maintenance. In urban installations, you see more complex systems and higher costs, but advanced ceramics provide superior contaminant removal.

Aspect | Decentralized Systems | Urban Installations |

|---|---|---|

Cost-Effectiveness | High; affordable for rural areas | Generally higher costs |

Ease of Use | Simple operation, suitable for low resources | More complex systems |

Contaminant Removal | Effective, but limited for certain pathogens | Advanced treatment options |

Maintenance | Requires user training for optimal performance | Typically managed by utilities |

Energy Consumption | Low; gravity-driven filtration | Higher energy requirements |

Service Life | Up to 5 years | Varies widely |

Note: When you select high-quality porous ceramics, you improve water purification efficiency and ensure safer drinking water for your community.

You gain several advantages when you choose porous ceramics for water treatment. These materials offer high removal efficiency for bacteria, sediments, and chemicals. The unique porous structure allows water to flow quickly while trapping contaminants. Compared to polymeric or metal filters, ceramics provide better chemical stability and resist corrosion from harsh cleaning agents. You can use them in both hot and cold environments because they withstand high temperatures and thermal shocks.

Porous ceramics also stand out for their long service life. With proper care, ceramic filters can last between 5 to 10 years, which is longer than many other filtration materials. Although the strength of ceramics may decrease over time due to erosion, you still benefit from their durability and reliability. The cost of these filters is another advantage. On average, you pay about $60 per square meter, which is lower than many commercial membranes. The materials, such as kaolin and quartz, make the filters strong and affordable. The fabrication process is simple, non-toxic, and does not waste water, making it a sustainable choice.

You also find that porous ceramics require only basic maintenance. You need to handle the ceramic pot carefully, clean it monthly, and replace it if it cracks or the flow rate drops. Regular scrubbing and soaking help keep the filter working well.

Tip: Porous ceramics help you reduce your environmental footprint. Industrial facilities using these filters can recover up to 95% of water and cut wastewater by 75%.

Despite their many benefits, porous ceramics have some limitations you should consider. The table below highlights the most significant challenges:

Limitation | Description |

|---|---|

Membrane Fouling | Contaminants can build up on the surface, reducing performance over time. |

Complex Manufacturing Process | Making ceramic membranes requires high temperatures and careful control, which increases complexity. |

Brittleness | Ceramics are brittle and can break under mechanical stress, so you must handle them with care. |

Limited Raw Materials | High-purity materials for some ceramics may be hard to find, which can affect supply and cost. |

You also need to monitor the filter’s performance. Over time, the porous structure can clog or erode, which lowers effectiveness. Factors like porosity, pore size, and durability all influence how well the filter works. If the pores are too large, you may not remove enough contaminants. If they are too small, the flow rate drops and maintenance becomes more frequent.

Maintenance is important. You should scrub the ceramic surface regularly, soak it in water or mild bleach, and replace the filter element when needed. If you notice cracks or a slow flow rate, it is time to change the filter.

Note: While porous ceramics offer many strengths, you must balance their benefits with these challenges to get the best results in water treatment.

You see that porous ceramics give you a powerful tool for water treatment. Their unique porous structure, chemical stability, and mechanical strength let you filter out bacteria and harmful substances. Ceramic membranes, especially those made from alumina, resist fouling and work well in harsh conditions. You benefit from their use in both municipal and industrial water systems. As demand for clean water grows, you will find more innovations, like advanced materials and improved filtration methods, making ceramics even more effective. Researchers continue to explore ways to boost performance, such as using turbulence or new materials.

Tip: Watch for new porous ceramics technologies, including metal-organic frameworks and nanoporous graphene, which promise even better water purification in the future.

Future Innovation | Benefit |

|---|---|

Metal-Organic Frameworks | Enhanced purification and selectivity |

Nanoporous Graphene | Higher efficiency and faster filtration |

You get high removal efficiency, strong chemical stability, and long service life with porous ceramics. These materials filter out bacteria, sediments, and chemicals. You also benefit from low maintenance and cost-effective operation.

You should scrub the surface of your porous ceramics with a soft brush. Soak the filter in clean water or a mild bleach solution. Replace the filter if you see cracks or a slow flow rate.

Porous ceramics can trap many bacteria and protozoa. Most viruses are smaller than the pores, so you may need extra treatment steps. You can combine porous ceramics with other purification methods for better virus removal.

You can use high-quality porous ceramics for up to five years. Regular cleaning and careful handling help extend their lifespan. Replace the filter if you notice damage or reduced performance.

Yes, porous ceramics made for water treatment meet strict safety standards. You can trust these materials to provide clean, safe drinking water when you use and maintain them properly.